|

| June 14, 2016 | Volume 12 Issue 22 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Metallic glue may stick it to soldering and welding -- in limited applications

By Thea Singer, Northeastern University

"They had a dream of a better way of sticking things together."

So says the company website for MesoGlue, a startup launched by Northeastern University's Hanchen Huang that features an intriguing metallic glue that shows real promise for sticking things together in the real world.

Those "things" are everything from a computer's central processing unit and a printed circuit board to the glass and metal filament in a light bulb. The "way" of attaching them is, astonishingly, a glue made out of metal that sets at room temperature and requires very little pressure to seal. "It's like welding or soldering but without the heat," says Huang, who is professor and chair in the Department of Mechanical and Industrial Engineering. Huang founded MesoGlue along with two of his PhD students.

In a new paper published in the January issue of Advanced Materials & Processes, Huang and colleagues, including Northeastern doctoral student Paul Elliott, describe their latest advances in the glue's development. Our curiosity was piqued: Soldering with no heat? We asked Huang to elaborate.

On new developments in the composition of the metallic glue:

"Both ‘metal' and ‘glue' are familiar terms to most people, but their combination is new and made possible by unique properties of metallic nanorods -- infinitesimally small rods with metal cores that we have coated with the element indium on one side and galium on the other. These coated rods are arranged along a substrate like angled teeth on a comb: There is a bottom ‘comb' and a top ‘comb.' We then interlace the ‘teeth.' When indium and galium touch each other, they form a liquid. The metal core of the rods acts to turn that liquid into a solid. The resulting glue provides the strength and thermal/electrical conductance of a metal bond. We recently received a new provisional patent for this development through Northeastern University."

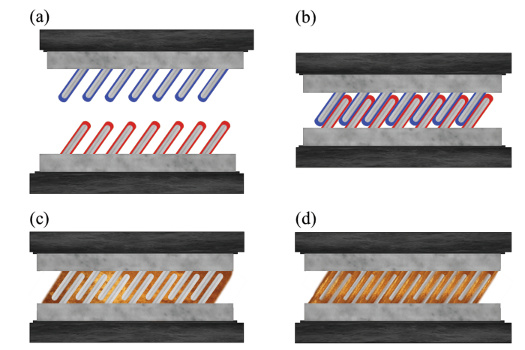

a) Coated rods are arranged along a substrate, like angled teeth on a comb. b) The teeth are then interlaced. c) When indium and galium come into contact, they form a liquid. d) The metal core of the rods turns that liquid into a solid. The resulting glue provides the strength and thermal/electrical conductance of a metal bond. [From "Advanced Materials & Processes," January 2016]

On the special properties of the metallic glue:

"The standard polymer glue does not function at high temperatures or high pressures, but the metallic glue does. The standard glue is not a great conductor of heat and/or electricity, but the metallic glue is. Furthermore, the standard glue is not very resistant to air or gas leaks, but the metallic glue is.

"‘Hot' processes like soldering and welding can result in metallic connections that are similar to those produced with the metallic glue, but they cost much more. In addition, the high temperature necessary for these processes has deleterious effects on neighboring components, such as junctions in semiconductor devices. Such effects can speed up failure and not only increase cost but also prove dangerous to users."

And a solderless connection in electronics means there is no chance for tin whiskering or whisker-??driven short circuits to occur.

What are some applications of the technology?

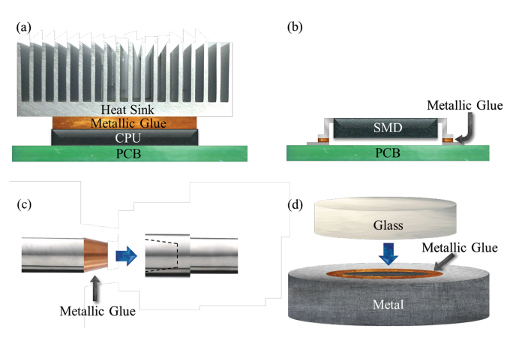

"The metallic glue has multiple applications, many of them in the electronics industry. As a heat conductor, it may replace the thermal grease currently being used, and as an electrical conductor, it may replace today's solders. Particular products include solar cells, pipe fittings, and components for computers and mobile devices."

Of course, once word got out about Huang's MesoGlue, he was bombarded with additional questions. He provides some basic details about the product and its properties here:

- The glue is mechanically strong. In our testing, it takes about 1,500 psi (or 10 MPa) shear load to break the glue.

- Once two solids are glued together, one has to break the glue like breaking a solder in order to remove one solid/component.

- The glue can work for nearly all kinds of solids: polymers, ceramics, metals, and any composites.

- The technology can be used to weld disparate metals, such as welding aluminum to mild steel. However, if you are thinking about large-scale steels, the cost will be too high to use the metallic glue. The technology can be cost effective for high-end applications like microelectronics.

- The nanorods grow on a solid surface via physical vapor deposition processes, and therefore form chemical bonds (much stronger than van der Waals forces) with the surface. For some solid surfaces, the direct chemical bonds can be weak (when it is "non-wetting"), and a buffer layer is introduced to strengthen the bonding.

- For the moment, surfaces to be glued have to be first prepared in Huang's lab. The company can also license the technology and help you set up the process at your location.

- The retail products that allow the user to do all the gluing themselves, similar to liquid glue or epoxy, are not quite ready for release.

A schematic illustrating applications of metallic glue: a) A CPU on a printed circuit board connected to a heat sink. b) A surface-mount device being attached to a printed circuit board. c) A press-fit pipe fitting for environments where welding is dangerous or impossible. d) A glass plate being attached to metal with a different thermal expansion coefficient to cover a cavity with a hermetic seal. [From "Advanced Materials & Processes," January 2016]

Learn more at www.mesoglue.com and contact Huang through the site if you have more questions.

Source: Northeastern University

Published June 2016

Rate this article

View our terms of use and privacy policy